Robotics shifts into gear for new competition season

February 8, 2017

After making it to FIRST Worlds Championships last year, the Whitman robotics team is gearing up for another competition season.

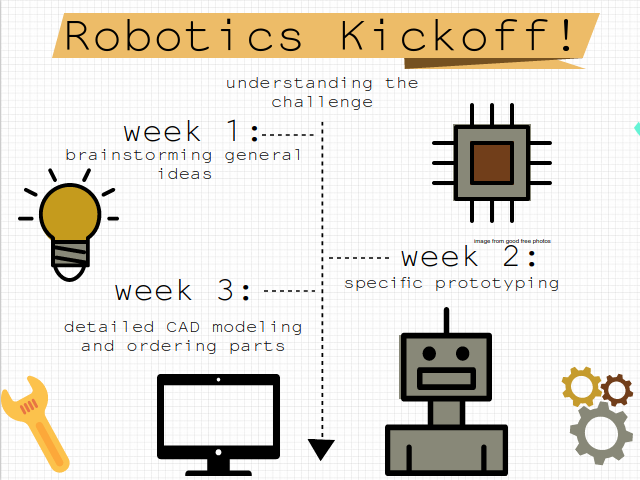

Every year, FIRST robotics announces a new challenge for high school robotics teams around the world to compete in. Each year’s event is announced in a “kickoff,” where teams watch a video explaining the game, receive a full manual of rules and regulations and gather together to start brainstorming. From there, teams have six weeks to completely plan, build and program their robot from scratch.

This year’s competition, “FIRST Steamworks,” revolves around using teams of robots to assemble and load an “airship” for take off. Points can be earned by retrieving and loading gears, shooting balls of “fuel” into the ship, and climbing a rope to mount the airship.

The drive team, which typically consists of three players, has been increased to five due to the nature of the game: the two drivers, one “coach” who strategizes gameplay, and two human players who operate on the field.

Because teams will make alliances with two other schools to work as a team in competition rounds, it isn’t necessary for the robot to complete all three tasks well.

“The main emphasis of our gameplay is scoring a lot of gears really, really fast,” programming head Ari Mindell said. “We designed this crazy base of our robot where it’s got like eight different wheels and it switches back and forth and what it allows it to do is move sideways and left and right and also go ridiculously fast.”

The robot will be able to complete the two other tasks as well, but these are of less priority.

In the past three weeks since the challenge has been announced, the robotics team has designed, prototyped, and created a full 3D model of the robot, the pieces of which began arriving on Jan. 23.

“It’s a really tight schedule—every single day there’s stuff blocked out that has to get done, and everyone’s been working really intensely,” Mindell said. “The next step now that our parts are in is to start fabricating and once that’s done, we just got to drive it, program it, and get it ready to be in competition.”